How is Foam Milling Used in the Automotive Industry?

Bakers Patterns | 21st September 2020

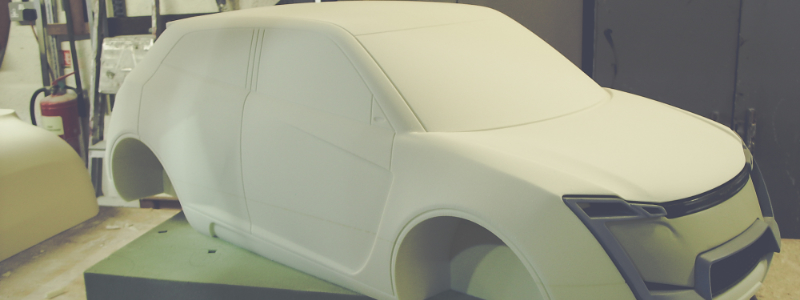

Polyurethane Automotive Model

As time moves swiftly on, manufacturers and leaders in the automotive industry will be looking for ways to make the manufacturing and the convenience of vehicles a lot smoother. Utilizing foam has become a standard for years in the automotive world, and there are continually new ways of inputting materials like in as each year passes.

Because foam does not weigh all that much, automakers are likely to put more into their future vehicles. Polyurethane and expanded polypropylene foams producers are saying that up to twenty-five pounds of the material will be placed into vehicle construction over the next decade. Automotive manufacturers are looking to reduce the overall weight of their vehicles, so this is likely to occur sooner rather than later.

Foam milling is a job that allows manufacturers in so many verticals to create new and never-before-seen products, but how exactly is foam milling used in the automotive industry, and what areas does it explore?

How Do You Create 3D Foam Sculptures?

The technology available today has enabled the creation of high-quality, more detailed, next-generation models. By combining the traditional technologies with modern CNC milling capabilities, you have the ability to design and build some awe-inspiring foam sculptures. When it comes to creating one of these impressive 3D models there are a few steps that you need to take.

Prototyping

Many manufacturing companies look to use foam milling in order to create the likes of a foam car prototypes and many other large-scale cosmetic models. Beforehand, a small design needs to be carried out in order to get an idea for the finished article. Foam prototyping companies know that foam is easy to work with for rough, early-stage designs, and foam can allow designers and engineers to get a basic sense of things initially.

Acoustic Insulation

Foam can be used for noise absorption and suppression. As automakers have progressed into the more modern methods and better-quality products, they’ve begun to implement more foam as a way of insulating the noise.

The Pros of Polyurethane for The Automotive Industry

It’s Versatile

PU can adapt very well in terms of design as well as being affordable to most. Comfort levels are the main reason it’s used in vehicle seating, but it’s also pretty durable due to the intensity of the material. It has a high resistance to heat, and its structural stability means it can be moulded into whatever is required.

It’s Lightweight

Most vehicles are known to consume fuel at a high rate. Due to the lightweight nature and qualities of polyurethane, the weight is drastically reduced and, therefore, massively improves the consumption and emissions of the vehicle. Steel is likely to stay for now as the primary material of vehicle structures, but materials such as PU are aiding the need for significantly reducing overall weight.

It’s Recyclable

It’s able to help reduce emissions, but PU has also become more popular due to its recyclability. It’s imperative that businesses and consumers show themselves to be greener and more aware of the damage that is caused to the environment. For a multitude of reasons, being more eco-friendly is nothing other than a huge positive.

That’s a Wrap

For over 35 years, Bakers Patterns has specialised in high quality, cost-effective, polyurethane and polystyrene models. From on-set modelling of polystyrene or polyurethane cars, sets, furniture, monsters, places and people through to the incredible launch events; and thanks to our adaptable skill set, we can handle any project, no matter the size.

Want to find out more? Get in touch and speak to a member of the Bakers Patterns team today on 01952 216165 or send us an email on info@bakerspatterns.co.uk. We look forward to hearing from you.

Polyurethane Automotive Models