There is no doubt that prototyping is an invaluable tool in the development stage of products and projects.

We believe it offers 4 key benefits for you.

- Flexibility to create solid objects for early evaluation,

- This then leads into design improvements and fine-tuning, which we find ends up with

- Increased finished product quality and finally

- It delivers certainty for the development process.

All of which enable you to showcase the product or project at a developed stage, thus reducing risk in the production process

Prototyping in the far east may seem like a logical step due to costs, but given the lack of control and extended lead times, not to mention the evaluation and sign-off lead times, manufacturing rapid prototypes in the UK is no doubt a very cost-effective and time-saving way of managing your NPD process.

Lapdog - The "Craft Anywhere" Tray.

The client required a prototype of their design, vital to ensuring the design functions correctly, before starting mass production; machined out of 100KG Polyurethane foam and painted with grey paint to seal the surface.

©Image by Bakers Patterns Ltd

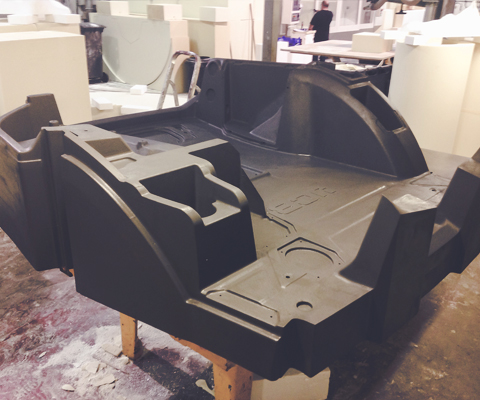

JCB - Vehicle Floor Pan

JCB required a very large scale precise floor pan of a development vehicle to help visualize and ensure correct fitment; cnc machined out of 35KG polyurethane foam and painted grey to seal the surface and closely resemble the planned production colour.

©Image by Bakers Patterns Ltd

Victoria + Albert - Bath Prototype.

The client required full-size bath prototype to help visualize a new range of products; cnc machined out of polystyrene.

©Image by Bakers Patterns Ltd